AUTOMATIC HOG CASING CLEANING LINE

The Automatic Hog Casing Cleaning Line is special designed for cleaning Hog Casings in an easy, efficient, and safe way, without damaging the Casings. This will result in high yields and reduced worker fatigue.

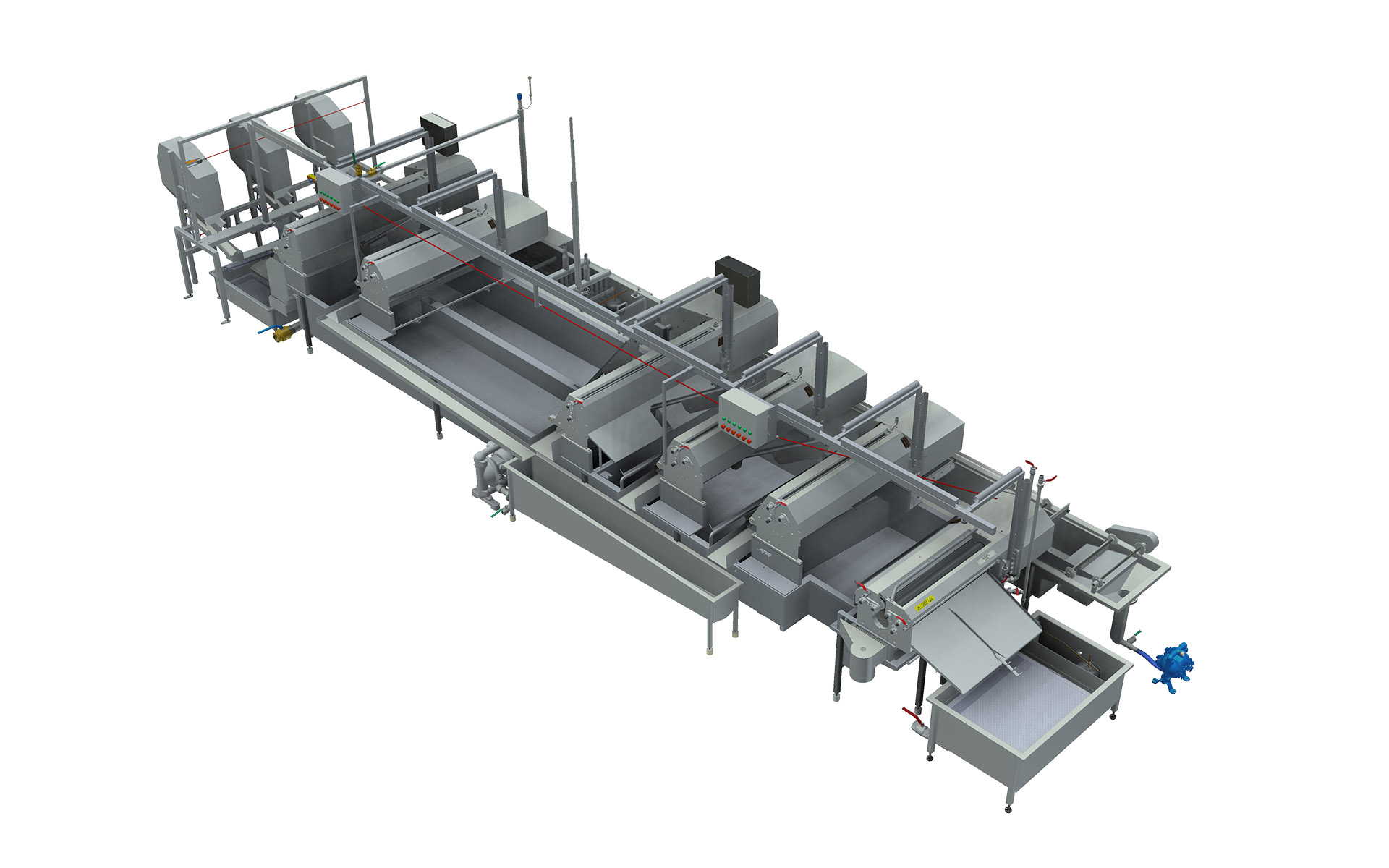

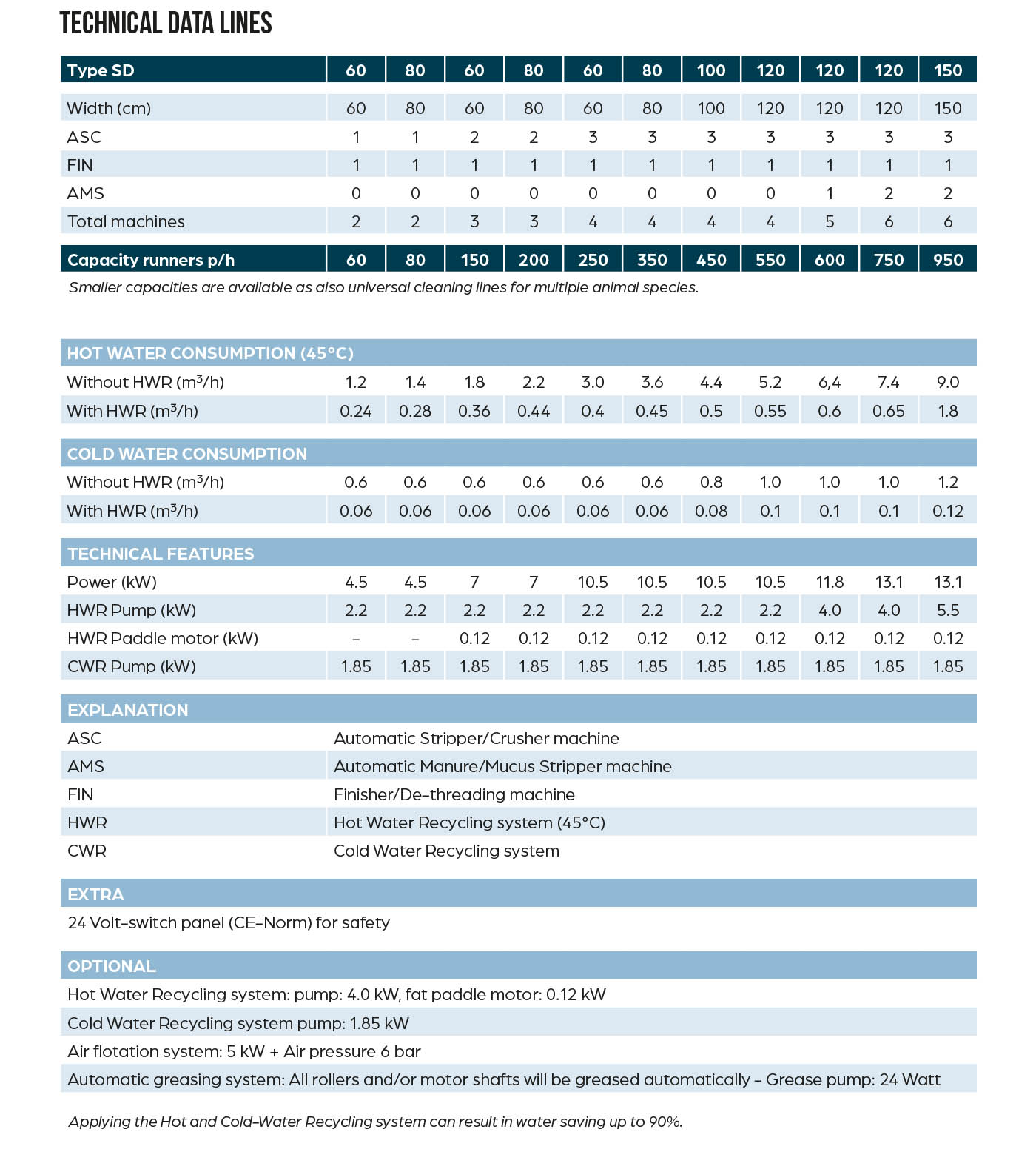

The capacity of the Automatic Hog Casing Cleaning Line depends on number of Machine Units in Line and the length of the rollers present in the Machine Units. The number of Machine Units in a Hog Casing Cleaning Line can vary from 2 up to 6 and the length of the rollers can vary from 600 up to 1500mm. The capacity is up to 950 Hog Casings per hour.

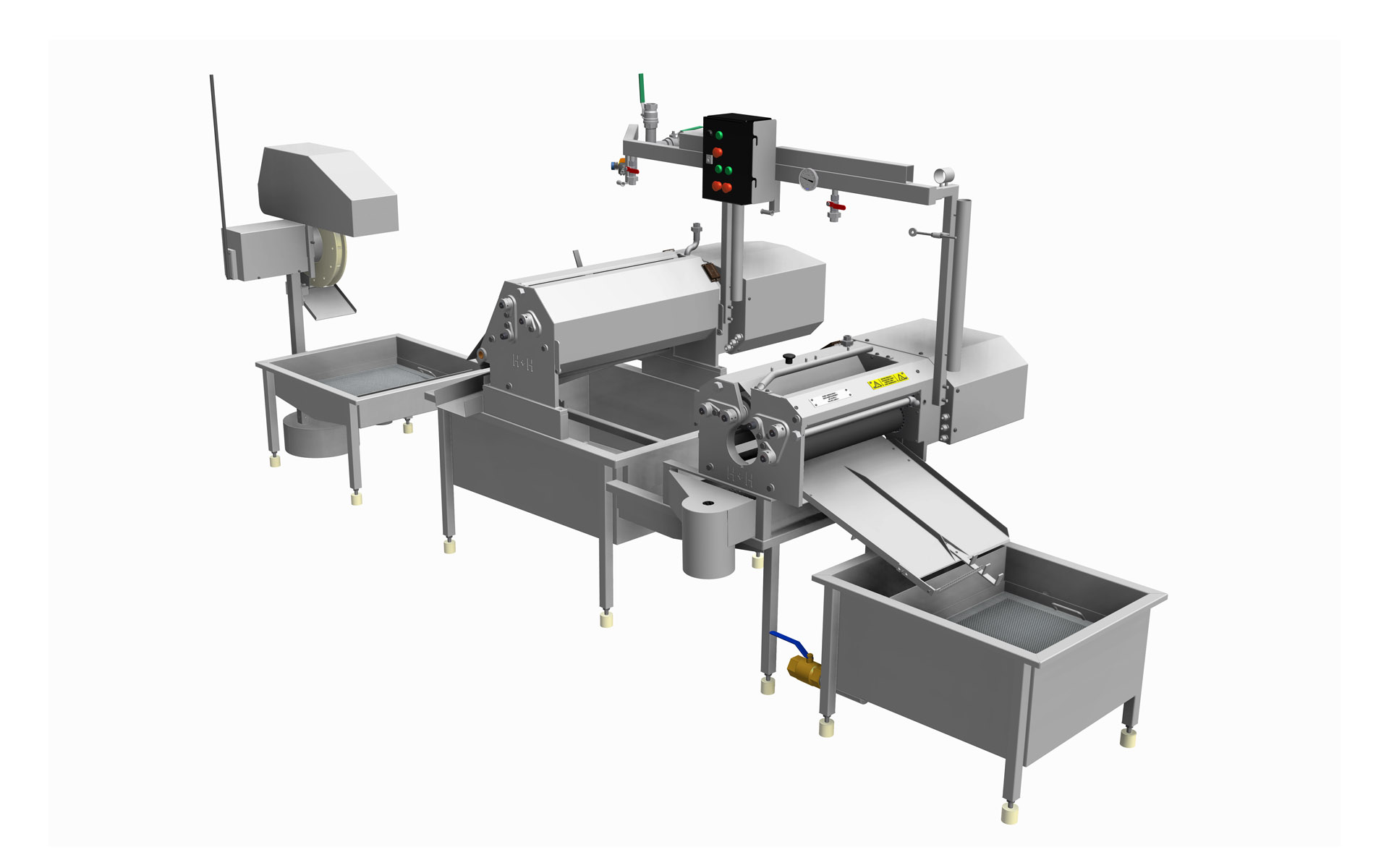

The First Machine Units in Line are Manure Stripper and Stripper/De-fatter Machines combined.

These Machine Units will thoroughly clean the casings by stripping out (squeeze by means of different types of Rollers) the Manure & Mucus. The last Machine Unit in the Hog Casing Cleaning Line is a Finisher-Machine. This Machine unit is special designed to takes off the outer skin (thread-membranes) of the Hog Casing.

The Mucosa will be collected in a chute and diverted to the side of the Machines.

The Hog Casing Cleaning Line is manufactured from high quality stainless steel and other corrosion resistant materials and is being supplied with Electric Control Panels according to NEN-EN-IEC 60204-1, including Start/Stop Buttons.

For maximum safety, the Hog Casing Cleaning Line is provided with Emergency Stop Buttons and an Emergency Stop Cord over the entire length of the working range.

This durable and reliable Hog Casing Cleaning is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.