CASING TUBING MACHINE

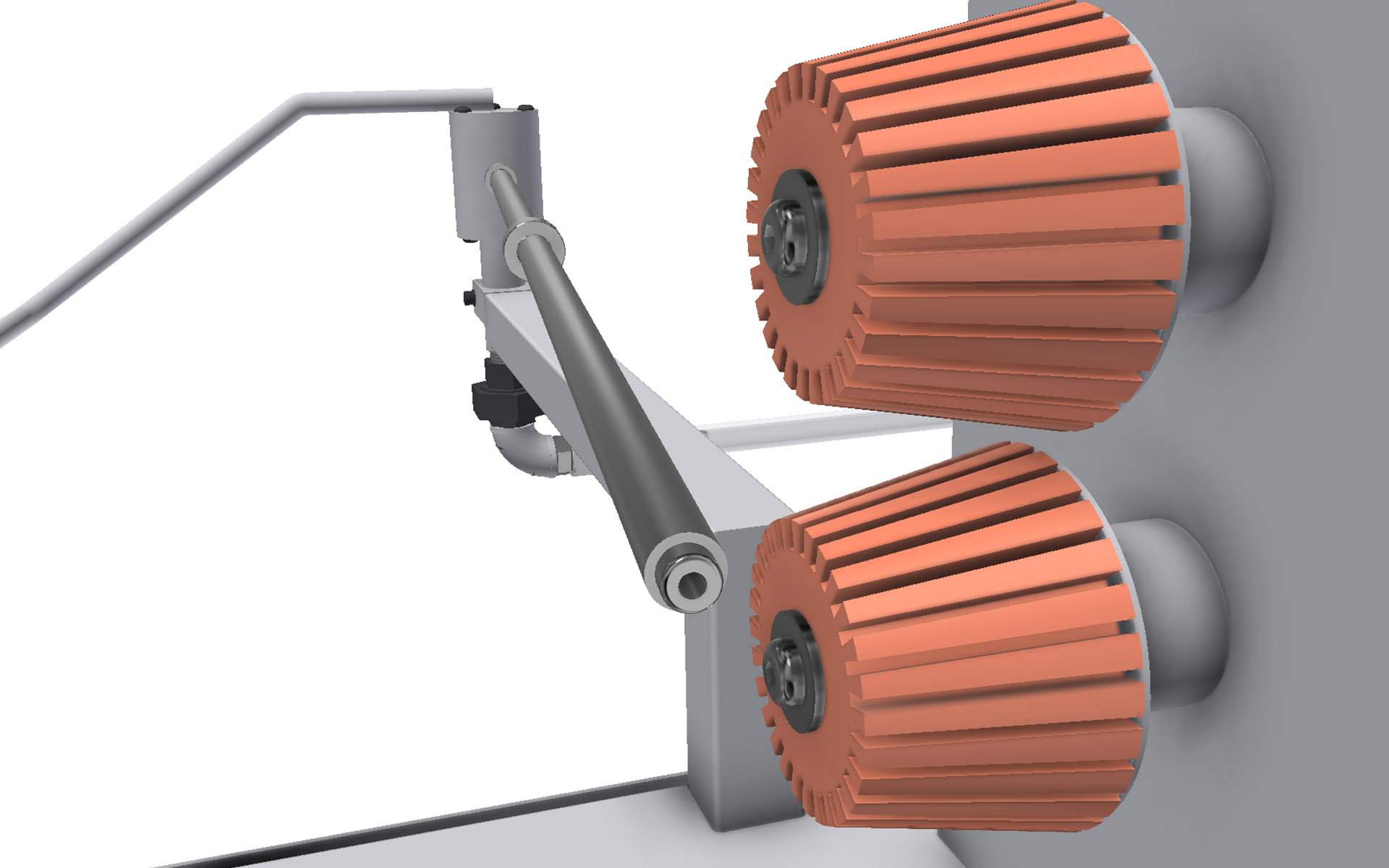

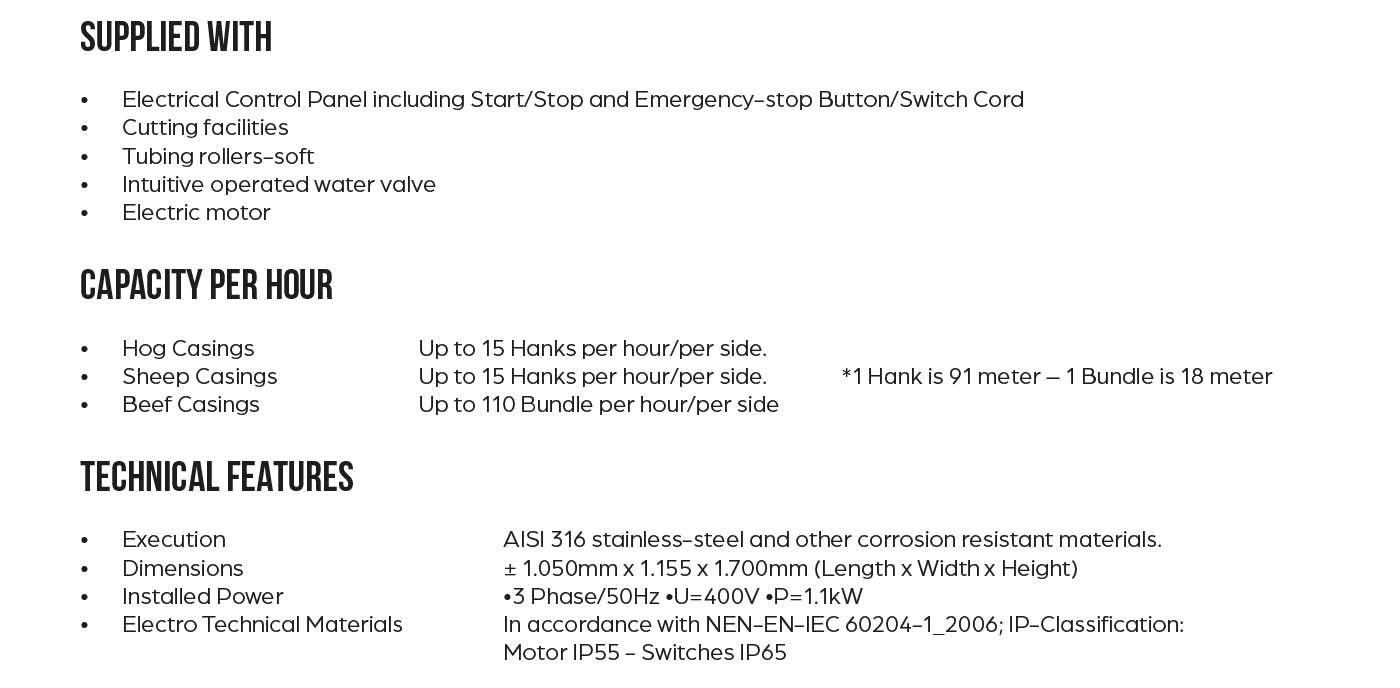

The double operated Casing Tubing Machine is specially designed for spooling processed Hog Casings, Sheep Casings and Beef Rounds in an easy, efficient, and safe way, without damaging the products. The machine is equipped with four motorized tubing rolls for optimum spooling of casings or rounds. This will result in high yields and reduced worker fatigue. The machine is suitable for soft and hard tubes. The double operated Casing Tubing Machine is equipped with two special cutting facilities for manually cutting the casings/rounds if required.

This tubing machine is designed for double operating – 2 operators on 1 machine. (In opposite direction-face to face)

The standard equipment of this machine consists of: stainless steel machine housing on base with water canalization, two sets of tubing pipes in diameters of Ø12mm; Ø16mm and Ø20mm for hard tubing and a set of four tubing rollers-soft, pre-installed on to the machine.

Optional, various types of tubing rollers and hard tube pipes are available. We can also provide adapters in various sizes for soft tubing.

The Casing Tubing Machine is manufactured from high quality stainless steel and other corrosion resistant materials. It is also supplied with an electric control panel including a start/stop and emergency-stop button.

This durable and reliable Casing Tubing Machine is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.