WATER TREATMENT

HOT WATER RECYCLING SYSTEM | TYPE: HWR

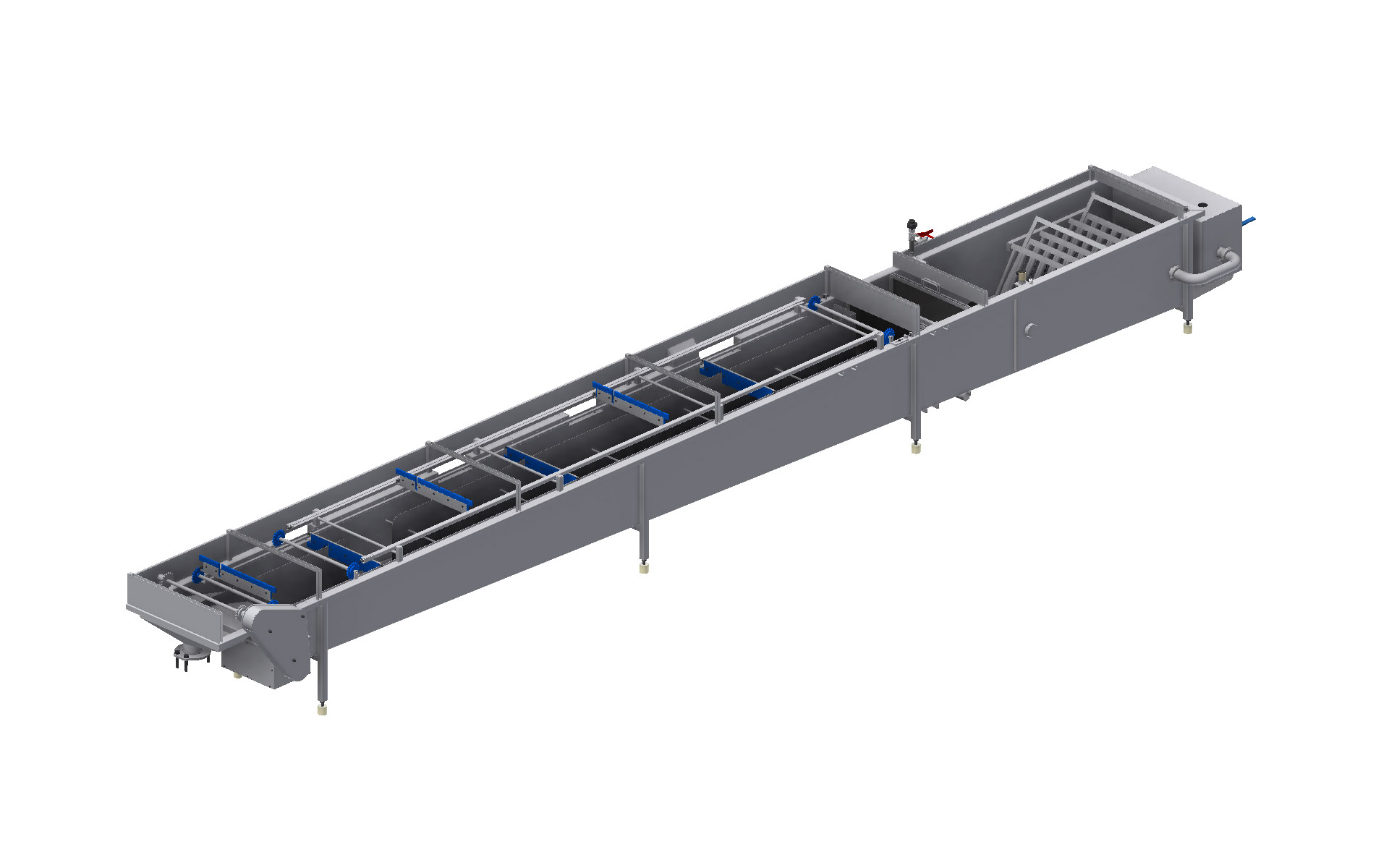

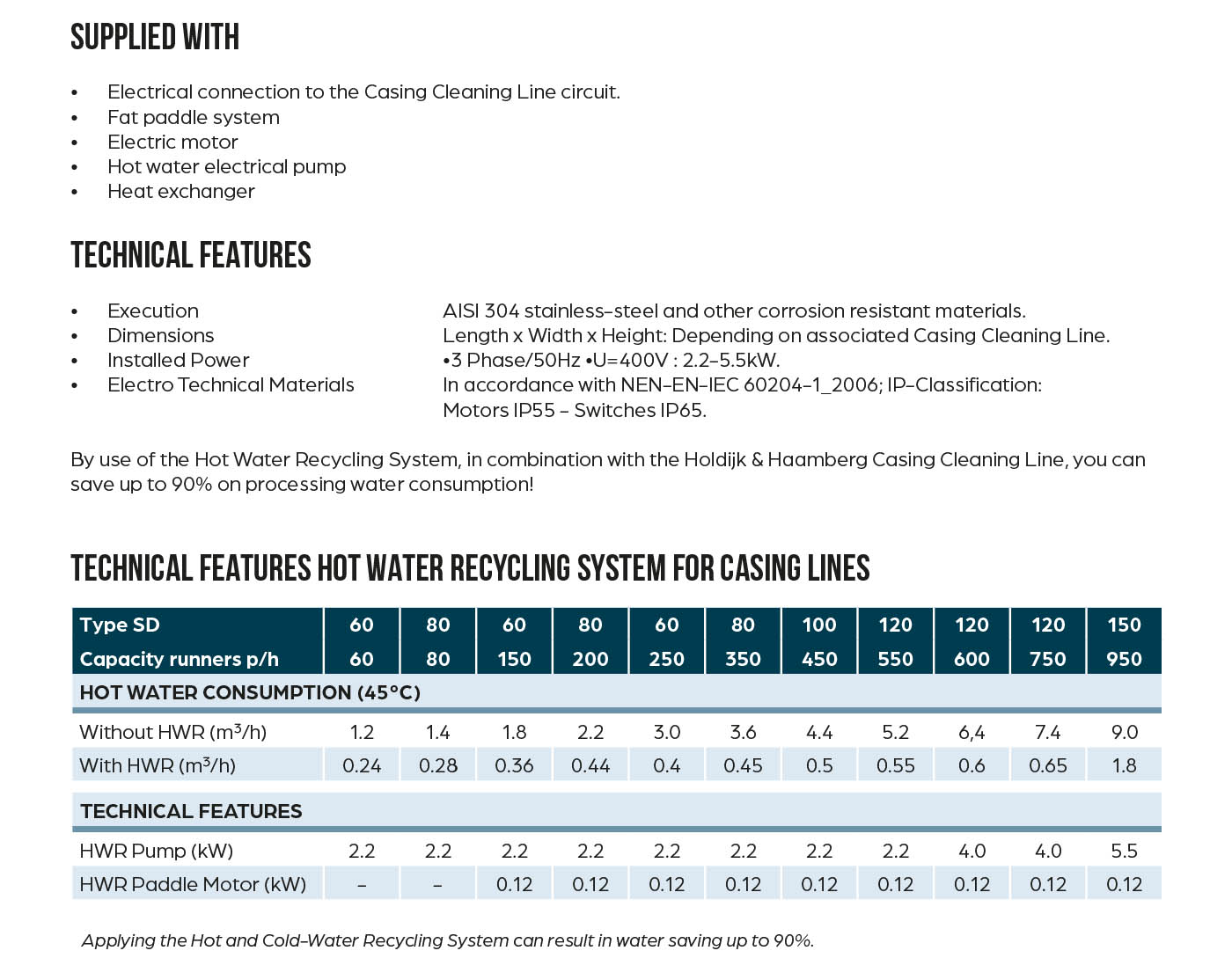

The Hot-Water Recycling System has been specially developed to reduce 90% of the hot water consumption, measured over an 8-hour work shift and will be positioned alongside the Casing Cleaning Line. The used water, coming from the machine units of the Casing Cleaning Line, flows into the system and will be cleaned, filtered and reheated by means of an integrated heat exchanger. This heat exchanger can be heated by steam, hot water or electricity, depending on the customer-specific situation in the gutroom.

The Hot Water Recycling System is equipped with a paddle system for separating and collecting the fat, coming from the cleaned casings. After this process, this reconditioned water will be pumped back to the various machine units of the Casing Cleaning Line, after which a new cycle will start.

To even increase the efficiency of the Hot Water Cleaning Process, this system can be equipped with an air flotation system specially developed by Holdijk & Haamberg. The fat, originating from the cleaned casings, is brought to the water surface at an accelerated rate by using microscopic small air bubbles.

The Hot-Water Recycling System is manufactured from high quality stainless steel and other corrosion resistant materials. Electrically it will be connected to the Casing Cleaning Line circuit and can be operated from there.

This durable and reliable Hot-Water Recycling System is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.

COLD WATER RECYCLING SYSTEM | TYPE : CWR

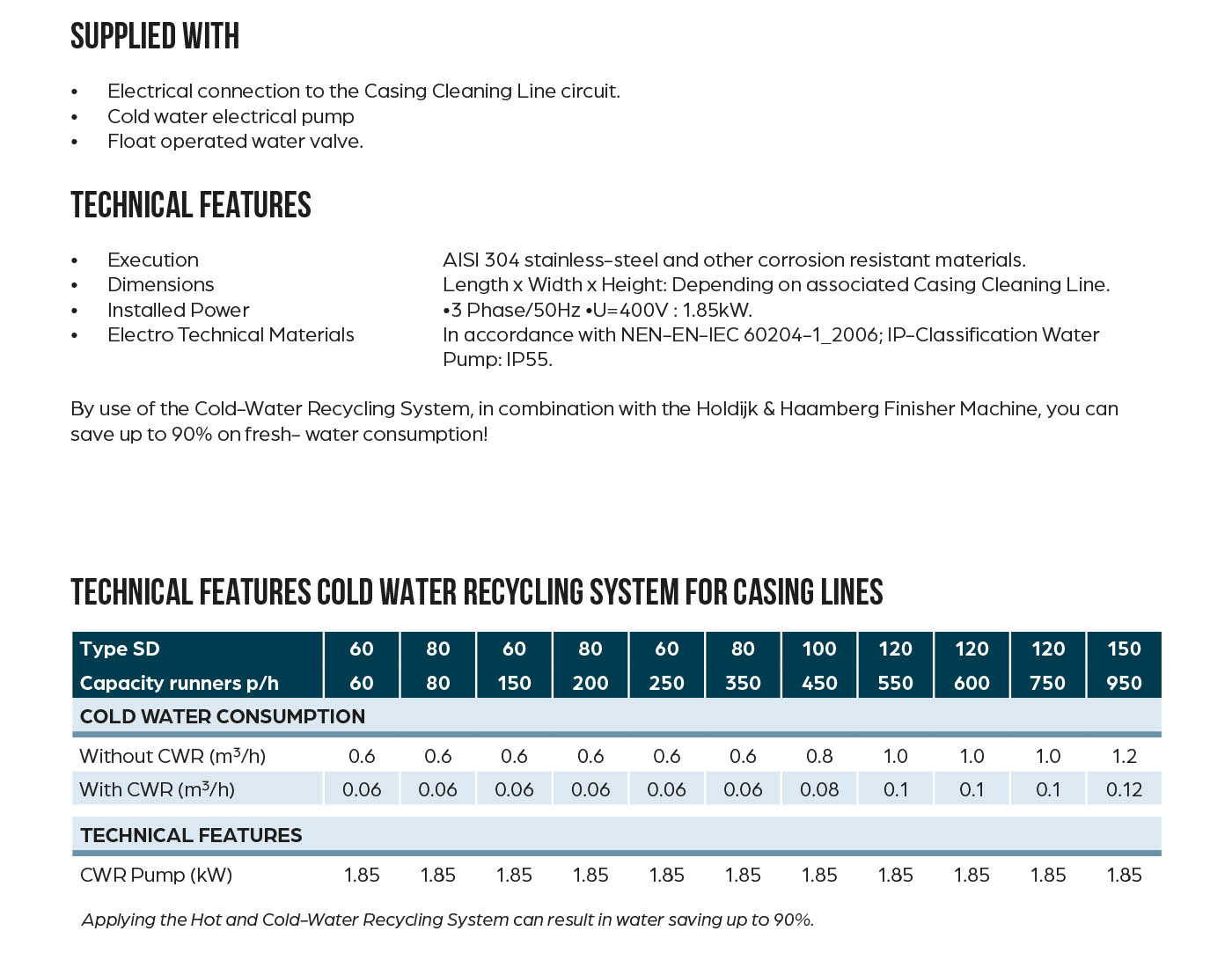

The Cold-Water Recycling System has been specially developed to reduce 90% of the cold processing water, coming from the last machine unit (Finisher Machine) of the Casing Cleaning Line, measured over an 8-hour work shift.

Working principle: The process water, coming from the finisher machine unit, is collected in this special water tank developed by Holdijk & Haamberg. This tank is equipped with a filter system, a float-driven fresh water supply and a Cold-Water pump. The primary purpose of this Cold-Water Recycling System is to quickly cool down the cleaned casings to ensure premium quality and, secondly, to conserve water for the finisher process.

The Cold-Water Recycling System is available in different sizes and can be used on all Hog and Sheep Casing Cleaning Lines.

The Cold-Water Recycling System is manufactured from high quality stainless steel and other corrosion resistant materials. Electrically it will be connected to the Casing Cleaning Line circuit and can be operated from here.

This durable and reliable Cold-Water Recycling System is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.