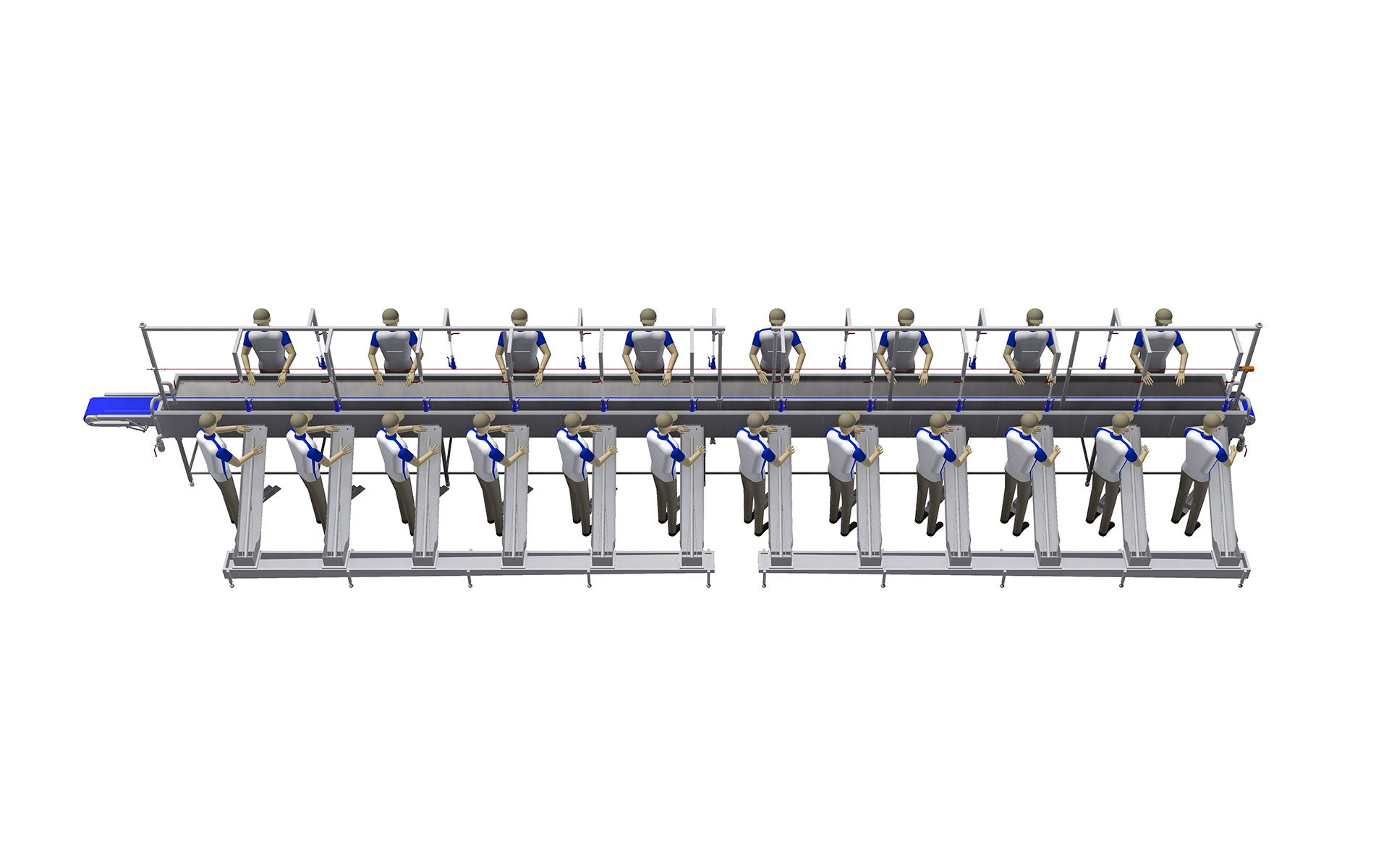

HOG CHITTERLING TREATMENT STATION

The Hog Chitterling Treatment Station is specially designed for Rinsing/Cleaning-, Turning inside-out- and Transporting the Hog Chitterlings in an easy, efficient, and safe way. By use of this Hog Chitterling Treatment Station, processing the Chitterlings can be performed much more efficiently compared to conventional ways of processing. The Hog Chitterling Treatment Station is very contributional to product quality and will ensure high yields.

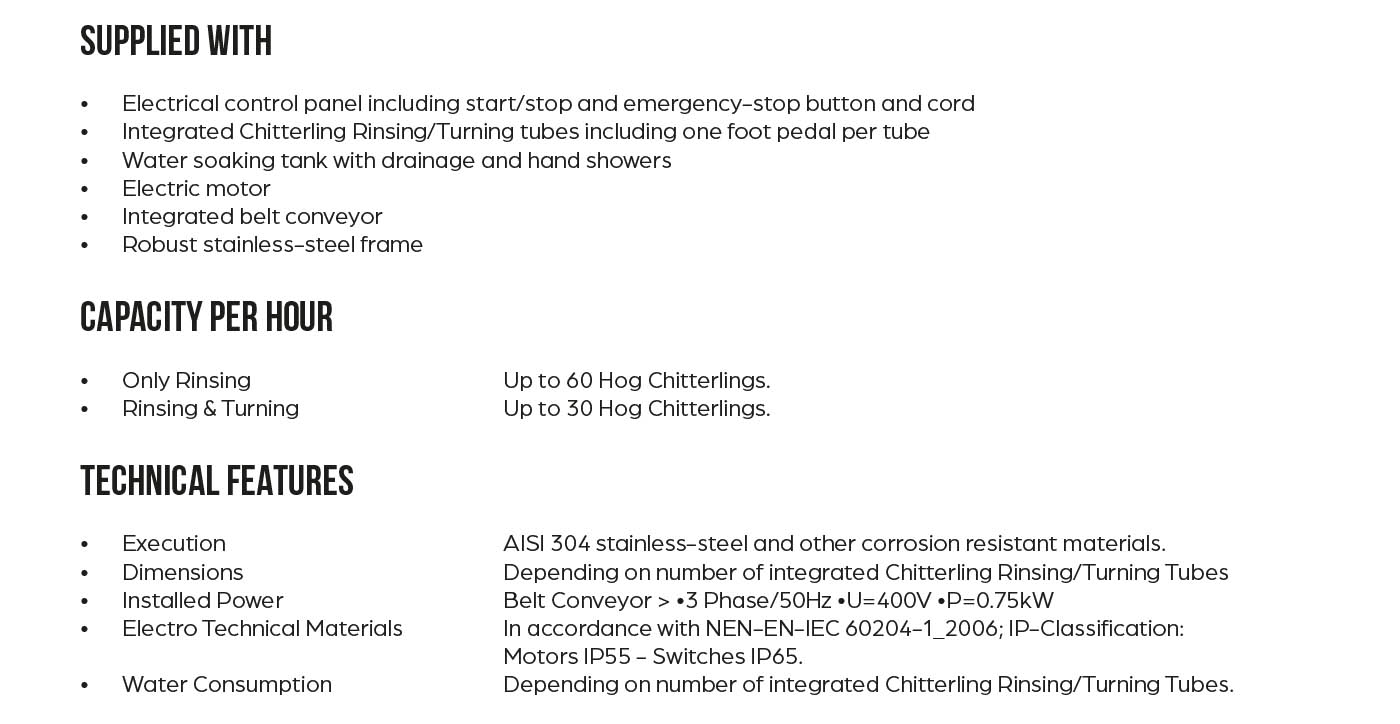

The capacity of a Hog Chitterling Treatment Station is always determined project-specifically. In practice, the Station can be equipped with up to 15 rinsing/turning tubes and an integrated conveyor belt with a length of up to 18 meters. The Rinsing capacity can be up to 900 Hog Chitterlings per hour. The Rinsing-Turning capacity can be up to 450 Hog Chitterlings per hour.

The Hog Chitterling Treatment Station is equipped with an integrated belt conveyor. This conveyor serves for an efficient supply of the Chitterling packages and for the transport of the residual material after the chitterlings manually have been extracted.

The Chitterling Treatment Station is manufactured from high quality stainless steel and other corrosion resistant materials. It is also supplied with an electric control panel with a stainless-steel cabinet, including start/stop and an emergency-stop button and -cord.

This durable and reliable Fatends Rinsing and De-fatting Conveyor is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.