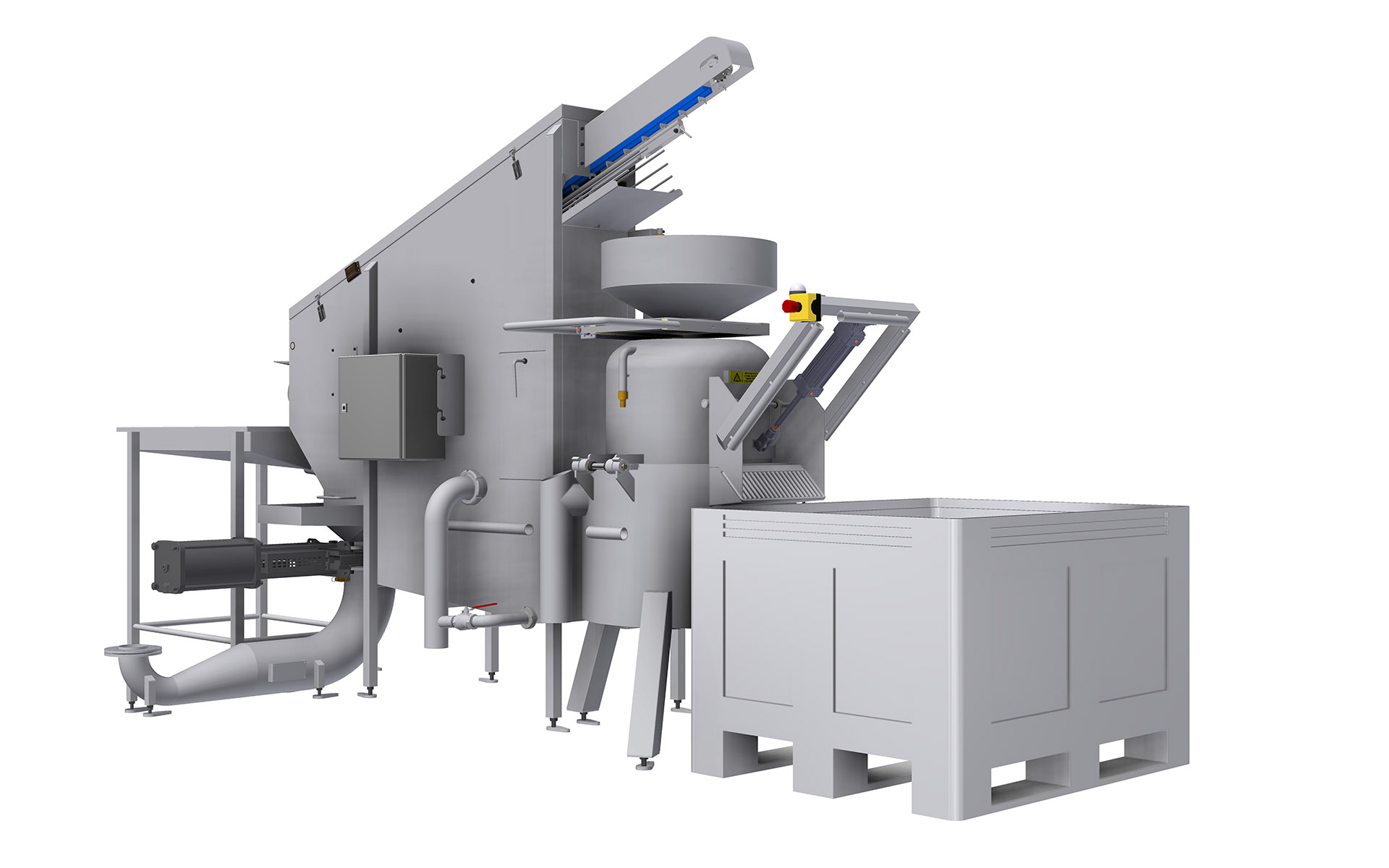

HOG STOMACH CUTTING & CLEANING

HOG STOMACH CUTTING & RINSING MACHINE

(BUTTERFLY CUT) | TYPE : ASCM

The Automatic Hog Stomach Cutting & Rinsing Machine is the result of our significant practical experience in the field, combined with thorough engineering. The special designed Automatic Hog Stomach Cutting & Rinsing Machine is equipped with a Motorized Circular Cutting knife and a Motorized internal transport system with Flushing Device for fully automated Cutting-open, Rinsing and Transport the Hog Stomachs with great comfort and ease, in an efficient, and safe way. This machine is designed for the, in technical jargon named, “Butterfly” Cut.

After the Hog Stomach is manually slid onto a pin, specially developed for this purpose, the Hog Stomachs are fully Automated guided through the cutting- and rinsing section of the Machine after which the processed Hog Stomachs can be collected for further processing. Use of this Automatic Hog Stomach Cutting & Rinsing Machine will result in high yields and reduced worker fatigue.

The Automatic Hog Stomach Cutting & Rinsing Machine is manufactured from high quality stainless-steel and other corrosion resistant materials. It is also supplied with an Electric Control Panel including a Start/Stop and Emergency-stop Button.

This durable and reliable Automatic Hog Stomach Cutting & Rinsing Machine is easy to use, to clean and to maintain. It has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.

SUPPLIED WITH

- Electrical Control Panel, including a Start/Stop and Emergency Stop Button.

- Motorized Cutting knife.

- Chain conveyor

- Water pump.

- Electric motor

CAPACITY PER HOUR – PER CHARGE

– Hog Stomachs : Up to 1200 Hog Stomachs per hour

TECHNICAL FEATURES

- Execution : AISI 304 stainless-steel and other corrosion resistant materials.

- Dimensions : ±2.500mm x 900mm x 2.100mm (Length x Width x Height)

- Installed Power : •3 Phase/50Hz •U=400V •P=4.0kW

- Electro Technical Materials : In accordance with NEN-EN-IEC 60204-1_2006; IP-Classification: Motors IP55 – Switches IP65.

- Water Consumption : ±0.8m3 per hour.

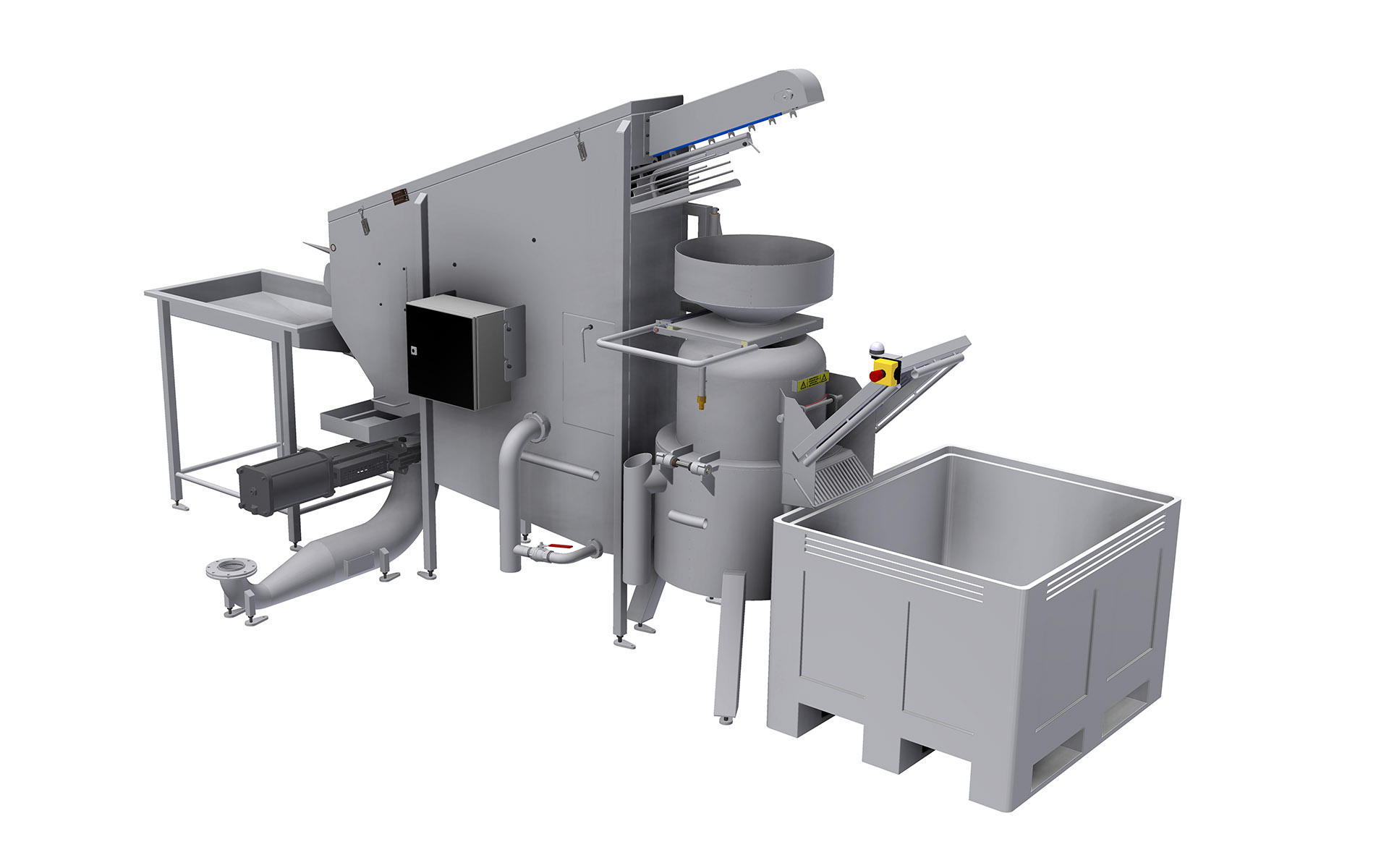

AUTOMATIC HOG STOMACH CUTTING, RINSING & CLEANING LINE

(BUTTERFLY CUT) | TYPE : ASCL

The Automatic Hog Stomach Cutting, Rinsing & Cleaning Line is the result of our significant practical experience in the field, combined with thorough engineering. The Automatic Hog Stomach Cutting, Rinsing & Cleaning Line consists of two seamlessly connected machines, The Automatic Hog Stomach Cutting & Rinsing Machine, and the Hog Stomach Washing-Cleaning Machine, to form a total solution for fully automated “Butterfly” Cut-open, Rinsed and Washed Hog

Stomachs. Use of this Automatic Hog Stomach Cutting & Rinsing Machine will result in high yields and reduced worker fatigue.

The Automatic Hog Stomach Cutting, Rinsing & Cleaning Line can be operated and maintained with great comfort and ease. The Hog Stomachs can be processed in an efficient, and safe way.

The Automatic Hog Stomach Cutting, Rinsing & Cleaning Line is manufactured from high quality stainless steel and other corrosion resistant materials and is being supplied with an Electric Control Panel according to NEN-EN-IEC 60204-1, including Start/Stop Button, Emergency Stop button and a separate 3 color LED column to indicate the Hog Stomach Washing-Cleaning Machine status.

This durable and reliable Automatic Hog Stomach Cutting, Rinsing & Cleaning Line has been carefully designed regarding ergonomics, food-safety requirements and CE-safety regulations.

All food process contact surfaces are in accordance with regulation (EC) 1935/2004.

SUPPLIED WITH

Hog Stomach Cutting & Rinsing Machine

- Electrical Control Panel, including a Start/Stop and Emergency Stop Button.

- Motorized Circular Cutting knife

- Water- and manure pump

- Chain conveyor

- Electric motor

Hog Stomach Washing-Cleaning Machine

- Electrical Control Panel, including a Start/Stop and Emergency Stop Button.

- Stomach Cleaning Disc

- Emergency Stop Button

- Pneumatic Door Cylinder

- Electric motor

CAPACITY PER HOUR – PER CHARGE

- Hog Stomachs : Up to 1200 Hog Stomachs per hour (Butterfly Cut)

TECHNICAL FEATURES

- Execution : AISI 304 stainless-steel and other corrosion resistant materials.

- Dimensions : ±4.250mm x 900mm x 2.100mm (Length x Width x Height).

- Total Installed Power : •3 Phase/50Hz •U=400V •P=4.0kW and •3 Phase/50Hz •U=400V •P=5.5kW.

- Electro Technical Materials : In accordance with NEN-EN-IEC 60204-1_2006; IP-Classification: Motors IP55 – Switches IP65.

- Water Consumption : ±1.4m3 per hour.